Design+ Technology Gateway in SETU Carlow are delighted to announce the arrival of their new Stereolithography 3D printer, the Raplas PR450 HD funded by Enterprise Ireland to complement the existing suite of polymer additive manufacturing machines on-site in their labs.

As a Technology Gateway that has received support from the Enterprise Ireland Capital Call, we have experienced the positive impact this program can have on Irish businesses first hand. Thanks to the funding we received, we were able to accelerate our research and development efforts, which allowed us to support Irish companies through innovation faster than we would have been able to without this funding. Additionally, the Capital Call program provided us with access to invaluable support services which allow us to further accelerate growth for businesses.

Overall, we credit the Enterprise Ireland Capital Call for contributing significantly to our success as a Technology Gateway, and we would strongly recommend this program to other Irish businesses seeking to innovate and grow in the technology sector.

Using the new Raplas PR450 HD additive manufacturing machine offers numerous benefits to businesses in various industries.

At Design+ we can work together with you to analyse your product portfolio, production lines, and supply chain to identify areas where 3D printing could be most beneficial. Based on the evaluation, we can then develop a strategy for integrating additive manufacturing into your operations, identifying the most suitable equipment and materials, and creating a plan for integrating 3D printing into your existing processes.

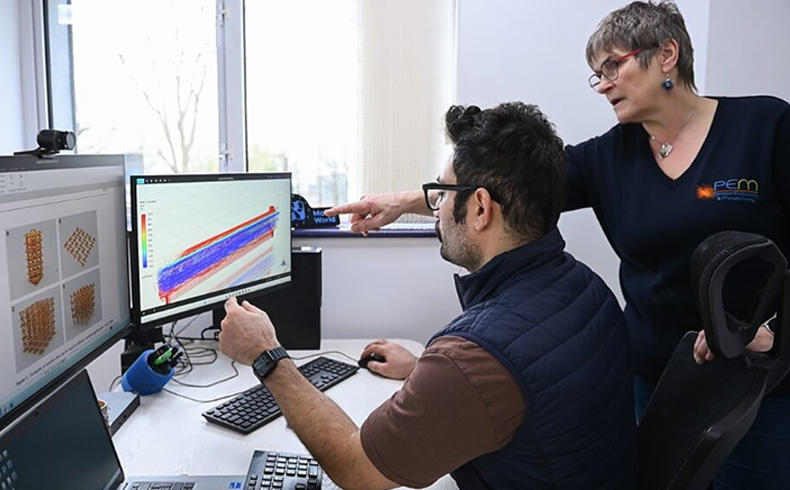

Above: New Stereolithography 3D printer, the Raplas PR450 HD funded by Enterprise Ireland

Raplas PR450 offers exceptional precision and can produce high-quality prints, making it an excellent option for businesses that need precise and accurate parts. It is also versatile, capable of producing both small and intricate designs as well as large and complex structures with its large print envelope of 450mm X 450mm x 400mm in the X, Y, & Z axis, making it an ideal choice for a variety of industries, such as automotive, aerospace, healthcare, and consumer goods.

The machine’s speed and efficiency are also significant benefits, as it can produce parts at a much faster rate than traditional manufacturing methods, resulting in reduced lead times and improved productivity. Additionally, businesses can significantly reduce production costs by using the Raplas PR450, as it eliminates the need for expensive tooling and moulds, and reduces material waste by using only the necessary amount of material for the product.

Another advantage of using our Raplas PR450 is its customisation capabilities, enabling businesses to create unique products tailored to their customers’ needs, improving customer satisfaction and setting themselves apart from competitors.

At Design+ Technology Gateway, our goal is to help you leverage its capabilities to drive innovation, streamline your processes, and achieve greater success in the marketplace. Let’s work together to explore the full potential of this technology for your business!