‘‘The world’s most forward-thinking scientists are developing and using animal-free methods that are actually relevant to human health for studying diseases and testing products. These alternatives to animal testing include sophisticated tests using human cells and tissues (also known as in vitro methods), advanced computer-modelling techniques (often referred to as in silico models), and studies with human volunteers.’’ (Former U.S. National Institutes of Health director Dr. Elias Zerhouni)

In vitro simply means ‘in glass’, meaning these tests are typically conducted in test tubes and similar equipment, as opposed to in vivo tests, which are conducted in the body itself.The MET approach to in vitro testing is centred around ‘In silicone elastomer models’ testing.

The in vitro testing, generally, assesses the safety of drugs, chemicals, cosmetics, and consumer products.

Our focus is the in vitro testing for the development of a wide range of implantable medical devices and minimally invasive surgical procedures, that require natural mechanical response of tissue and organs replication. One solution to achieving this type of replication is given by silicone elastomeric materials, also known as silicone rubbers.

Silicone rubbers have characteristics of both inorganic and organic materials and offer a number of advantages not found in other organic rubbers. Silicone rubbers are physiologically and chemically inert, they have fine electrical properties and flame retardancy, superior resistance to heat and cold and transparency. Silicone molecules are helical and intermolecular force is low, resulting in high elasticity and high compressibility. Silicone rubber is hydrophobic, it can be immersed in water for long periods with virtually no effect on mechanical strength and electrical properties.

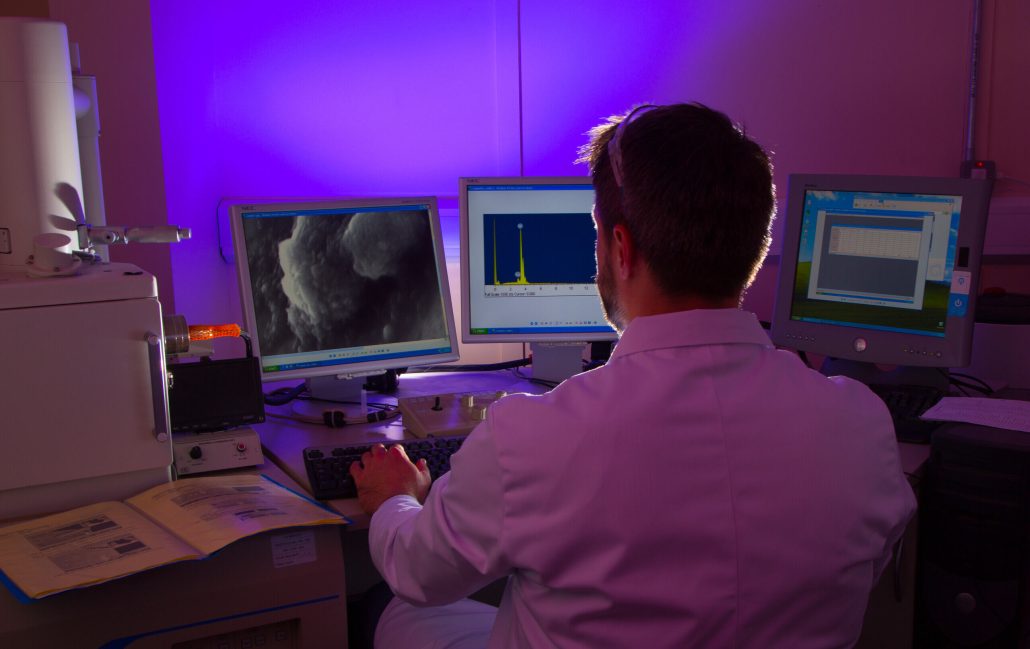

Medical and Engineering Technologies (MET) Gateway developed, over the past years, a great understanding of the importance of in vitro performance testing for medical devices, by using silicone elastomeric models. Interdisciplinary teams of scientists, clinicians and engineers work together, within MET, to identify and understand disease scenarios, to design and fabricate clinically relevant anatomical models and to develop relevant in vitro test methods for medical devices development.

The anatomical models can be idealised or patient-specific. Patient-specific silicone elastomeric models are developed from translated medical data obtained from clinics and hospitals, in Ireland and around the world, in the form of CT/MRI scans. Through this approach a wide variety of human anatomical features and disease scenarios can be replicated, which cover the vascular, cardiac, pulmonary and any other relevant areas of interest for the clinical community and the MedTech sector.

The models and can be used on their own or as part of complex electromechanical setups/rigs. These rigs will allow for flow and pressure monitoring, video recording, data acquisition, and they make use of steady or pulsatile pumps, actuators, controllers, heated water baths and any other relevant equipment deemed necessary for any in vitro testing setup. Such setups are controlled by one or multiple computers and are called simulators. These simulators make use of body mimicking fluids and other relevant fluids, to replicate the healthy and/or diseased cardiac function as required by testing conditions. Therefore, certain desired human physiological scenarios such as the pulsatile blood flow through blood vessels and organs, organ motion and haptics, can be replicated in vitro.

A wide range of in vitro tests can be performed to determine or demonstrate medical devices performance within MET laboratories such as:

- Catheter testing: navigation/training/demos using 3D anatomical models for cerebral vasculature, coronary vessels, peripheral vasculature or the aorta artery, under live fluoroscopy.

- Stents and stent-grafts testing for deployment evaluation under live fluoroscopy,

- Artificial heart valves visualisation and leak testing under ultrasound scanning,

- Radiopacity testing of devices marker bands aligned to ASTM F640-20 standard under fluoroscopy.

Important advantages of in vitro testing with MET’s models and simulators include:

- Higher speed and greater accuracy in the evaluations of medical devices.

- Validation of mechanism of action.

- Possibility of performing complex assessments.

- More reliable tests results compared to animal models.

- Helps build a strong and original scientific dossier, in order to highlight the technological and competitive advantages.

- Cheaper than animal testing.

- Ethical benefits.

MET Gateway is working, continuously, with researchers, clinicians and MedTech clients towards improving the clinical relevance of its in vitro models and simulators. Therefore, MET is looking to expand its modelling capabilities towards complex in vitro models, in particular, bioprinted tissue. This approach is intended to represent complex aspects of human biology in practical experimental setups.

To find out more about MET Technology Gateway, check out their website or follow them on LinkedIn.