The Smarter Factory Technology Gateway, based in TUS MidWest is a centre of excellence for Industry 4.0/5.0, driving digital and green transformation to support innovative enterprises and shape the future of manufacturing. Co-funded by the Government of Ireland and the European Union through the Southern, Eastern & Midland Regional Programme 2021–2027, the Smarter Factory Technology Gateway will partner with all of industry in the manufacturing value chain, in research projects leading to impactful innovation.

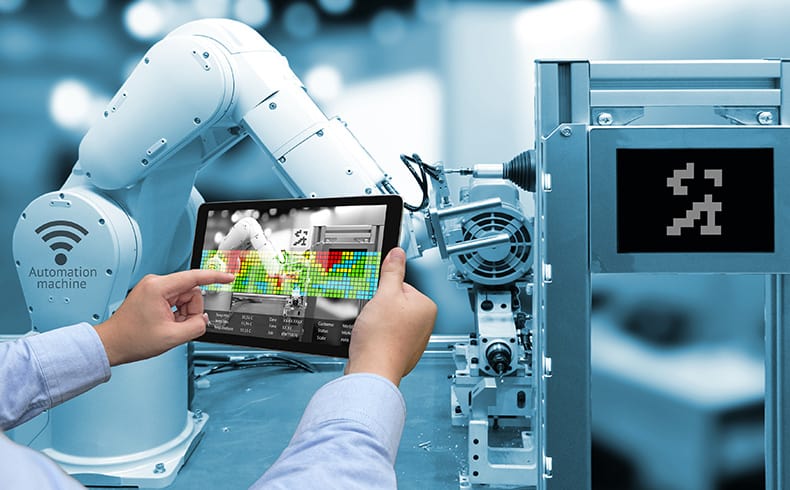

At the core of these research partnerships lies a shared belief in the power of data. The Smarter Factory’s emphasis on harnessing data, through cyberphysical systems (CPS), the Internet of Things (IoT) and edge devices, lays a foundation for the effective deployment of intelligent systems, cognitive robots, computer vision systems and artificial intelligence (AI).

Shaping the future of Manufacturing

IDEAM and the Smarter Factory Technology Gateway will cooperate synergistically, impacting industries ranging from multinational corporations to the dynamic landscape of small and medium sized enterprises (SMEs) and startups. Together, these initiatives are not merely envisioning the future of manufacturing; they are actively shaping it. The University’s Research Institute provides the intellectual foundation and expertise while the Smarter Factory Technology Gateway brings the practical application of these innovations. This dynamic collaboration is driving progress, fortifying businesses with advanced technologies, reducing costs and enhancing performance.

The future of manufacturing is not a distant prospect; it’s a tangible reality being shaped by the transformative partnership between academia and industry at TUS.

What expertise is available at Smarter Factory

The University’s Researchers bring deep expertise in industrial automation, manufacturing systems, control systems, data acquisition, machine learning, simulation, digital twins, algorithm development, intelligent business tools and the industrial data space. A core priority of the gateway will be the practical applications of these advanced digital technologies through demonstration in real-world industrial scenarios, where new insights from smarter data can drive improved quality, predictive maintenance, increased capacity, cost reductions, improved efficiency and more sustainable operations.

How can Smarter Factory assist

Supported by an Industry Advisory Board, industry partners and regional stakeholders, the activities and strategies for the Smarter Factory Technology Gateway are focused on enabling industry to address the opportunities arising from Industry 4.0/5.0, the digitalisation of manufacturing, and advanced in Artificial Intelligence (AI) to support the development of agile, sustainable and resilient manufacturing operations and exploit the innovation and funding potential of National and European Research Programmes.

Supports available

The Smarter Factory Technology Gateway provides dedicated Digital Strategists to support and connect with companies. They will assess business models, metrics and challenges; identify digital maturity; address knowledge gaps; and guide value-driven business transformation.

Specialist training programmes are available to nurture the talent needed for industry-wide digital and green transformation, including;

- Masterclasses in Data Analytics & Machine Learning, Cyber-physical Systems & IoT, Databases and Data Visualisation, and Digital Twins in Production Systems

- Specialist Skills Modules in; Industrial Control Systems (DeltaV, Siemens, Allen-Bradley, Mitsubishi), Machine Vision systems (Cognex, Keyence), Robotics (UR, Kuka, ABB, Mitsubishi, Comau), and in many areas of instrumentation, supervisory control and data acquisition

- Certificate in Leadership in Digitalisation of Manufacturing

- Masters in Digitalisation of Manufacturing (Collaboration with Irish Medtech Skillnet)

Specialist Research & Training Labs

Specialist Research and Training Labs are available at the TUS Moylish and Coonagh Campuses in Limerick to enable Companies to ‘Test before they Invest’ – completing development and experimentation on software tools and/or equipment in a pilot lab or testbed before deploying to the factory environment. [See details of labs and equipment below]

Industrial Control Lab

Hosts a Large-Scale Distributed Control System (DCS) used for production management and maintenance in the highly-regulated Pharma, Bio-pharma, food and energy industries. The equipment is available for collaborative projects on digitalisation in process industries, data acquisition and analytic applications, predictive maintenance and specialist skills training. The labs are equipped with advanced industrial controls systems (DeltaV, Siemens, Allen Bradly, Mitsubishi), and a wide range of instrumentation test and demonstration rigs.

Smarter Factory Lab

Hosts a wide range of Robotic, Cobotic and Visions Systems for zero-defect automated inspection and human-centric production support through augmented learning methods, and optimised product assembly workflows. The equipment is used for autonomous product assembly training for piece-part assembly work in the regulated manufacturing industries. The labs is equipped with industry standard Machine Vision systems (Cognex, Keyence) and Robots (UR, Kuka, ABB, Mitsubishi, Comau).

SPARC Lab

Hosts an industry-standard Substation with high-voltage and electrical power distribution, switching and monitoring equipment. The equipment is used for electrical grid and renewable energy simulation, demonstration, test and training activities. The lab includes a suite of Energy Efficiency and Renewable Energy equipment – Solar PV, Wind, Heatpump and electric vehicle technology, fitted with data-logging systems, monitoring and control equipment.

Machining ‘Maker’ Centre

Hosts an integrated Machining ‘Maker’ Centre: equipped with a Spinner U620 Siemens Sinumerick 5 axis Milling machine, a Mazak QuickTurn 250MSY CNC lathe, a Fanuc Robodrill 3 axis High speed Milling Machine, various Co-ordinate Measuring Machines (CMM), inspection and test equipment. The equipment is used for automated destructive and non-destructive testing of component parts, linked to hybrid AI CAD/CAM tools for parametric design, rapid prototyping and testing of parts and closed loop feedback.

Virtual Engineering Lab

Used for the generation of factory, production, and equipment data-sets for real-time training of Generative AI applications in manufacturing. The equipment is used for data acquisition and to provide validated data-as-a service for the prototyping of AI Tools and machine learning / deep learning algorithms. Application areas include production planning, campaign building strategies, predictive maintenance and Digital Lean applications. The lab is equipped with industry data-sets, virtual industrial environments (Visual Components /NX/Unity/Emulate 3D/ 3DEXPERIENCE), digital twins of production spaces, industrial data space demonstrators (UNS, Gaia-X, IDS) and facilities for secure co-creation and system integration.