KORE Insulated Foundation System FEA Analysis

Energy efficient deep retrofit solutions

Kore Insulation was founded in 1997, initially manufacturing expanded polystyrene boards for use in building insulation.

In 2010 KORE launched the innovative Insulated Foundation System, offering low floor U-values while eliminating the wall-to-floor thermal bridge. The system has received full NSAI Agrément certification, and is currently used by major developers across Ireland, with sites ranging from 10 units to over 100 units.

In partnership with SEAI, the KORE Warmer Homes Scheme delivers energy efficient deep retrofit solutions. KORE has added Roof and wall ventilation products to its extensive range of energy efficiency solutions.

KORE has received numerous awards, most recently the SME award for Exemplary Energy Performance at the SEAI Energy Awards 2021, and finalists in the Guaranteed Irish Business Awards 2022.

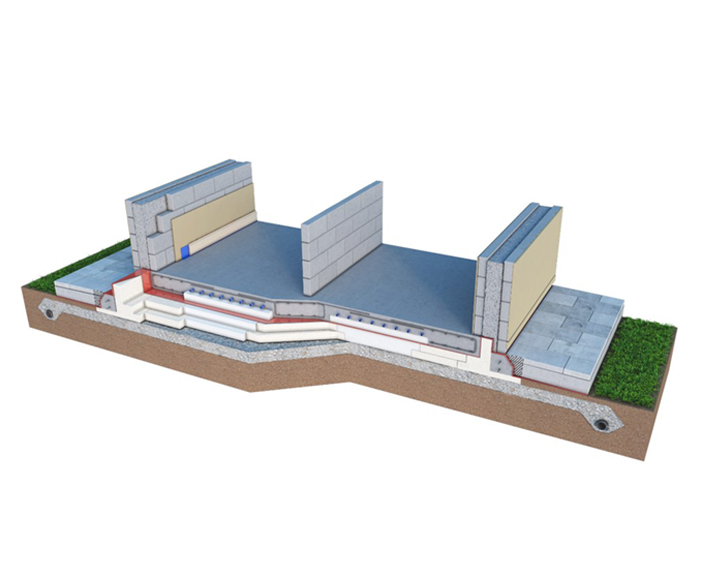

The KORE Insulated Foundation System consists of expanded polystyrene (EPS) combined with a reinforced concrete slab, providing a complete foundation and ground floor solution with excellent thermal performance.

Structural & thermal performance assessment

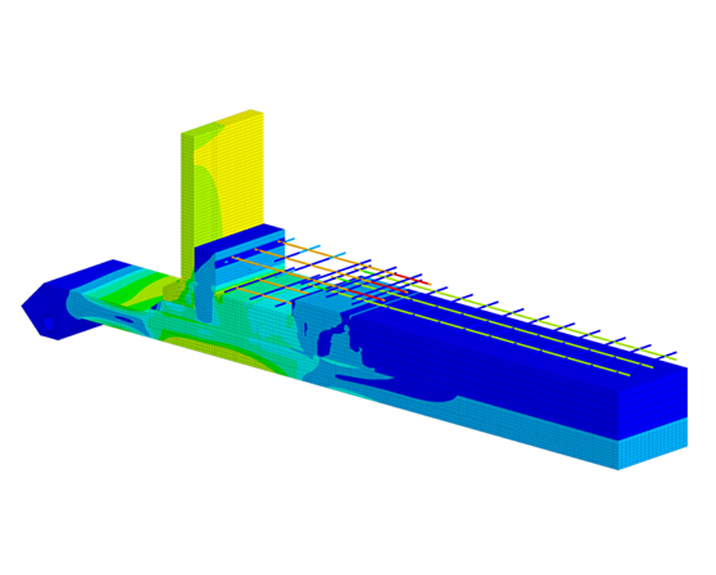

As part of continual design optimisation and improvement, KORE approached SEAM Research Centre at the South East Technological University with the brief to carry out a detailed structural and thermal performance assessment of the system across a wide range of operational conditions. Modelling of the design through Finite Element Analysis (FEA) allows comprehensive insights into design performance to be gained, which cannot readily be obtained from conventional methods such as hand calculations.

SEAM developed structural and thermal Finite Element Analysis (FEA) computational models of the KORE Insulated Foundation System, and analysed design performance across a wide range of operating scenarios. Structural FEA analysis provided insight into the load distribution and detailed stress state within each component and material, allowing the performance of each component to be quantified, and enabling several design options to be assessed.

A thermal FEA analysis model of the KORE Insulated Foundation System deployed in a domestic dwelling was developed, allowing the flow of heat energy across several heating and cooling cycles to be modelled. By developing an equivalent model of a traditional foundation, the increased energy efficiency and associated energy cost savings of the KORE Insulated Foundation System compared to a traditional foundation solution was demonstrated.

25

years in business

1

global leader

70

employees

“Working with SEAM was a very positive experience for us at KORE Insulation. The team were able to comprehend our specific requirements and tailor analysis and study to deliver our required outcome. The level of engagement and communication by SEAM is to be commended and they worked closely with us to ensure we understood the details of the analysis, and were at the same time eager to take direction and tailor the analysis to suit our requirements.

The structural & thermal FEA work has been very valuable to us to assist in meaningful communication within the construction industry offering learnings that were previously not available to design & construction professionals. We would happily recommend SEAM.”

Andrew Butler – Technical Business Development Manager

The KORE Insulation & SEAM Technology Gateway partnership

By partnering with SEAM, KORE were able to leverage the use of detailed computational FEA models in order to gain an increased understanding of the structural and thermal performance of the Insulated Foundation System. The analysis results are key in quantifying the performance and demonstrating the effectiveness of the technology across a wide range of conditions.

SEAM utilises engineering simulation and various other analytical and non-destructive (CT scan) techniques to solve problems across a wide variety of industries. As well as proficiency in CFD for the analysis of fluid flow phenomena, SEAM has expertise in structural analysis involving Finite Element Analysis (FEA), The application of these analysis techniques has resulted in cost reductions for SEAM’s client companies through reduction in physical prototyping, improved operating performance, and improved product lifespan