In our ‘Meet the Team’ series, we bring you a range of staff interviews from across the Technology Gateway Network.

Today we introduce Russell Macpherson, Technology Gateway Manager at PEM Gateway, based at ATU Sligo.

Tell us a bit about PEM Technology Gateway?

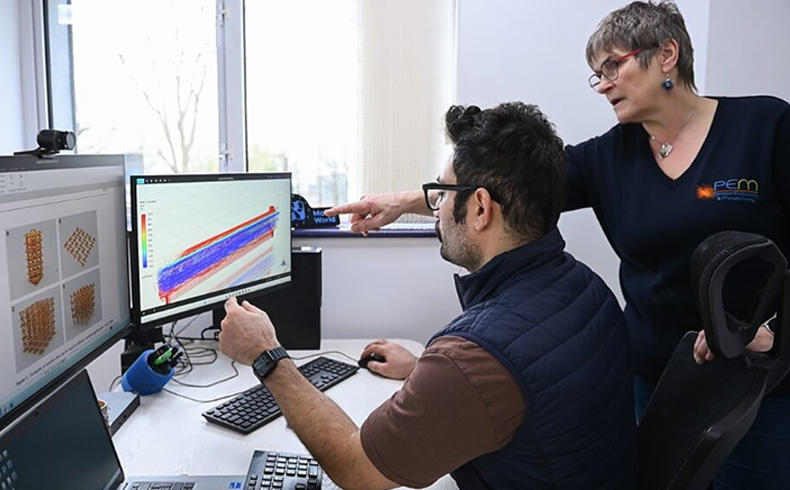

The PEM Technology Gateway provides industry with engineering and technical solutions and process improvements across the full product lifecycle, with specialisation in design for manufacture (DFM), product design and development in the engineering and manufacturing sectors. PEM has a team of dedicated Principal Investigators (PIs), engineers, academics, and research staff, all of whom are experts in their fields based in ATU Sligo to use their knowledge to help industry.

We work with companies, across a range of sectors on projects that help solve technical challenges they are experiencing or innovation they wish to exploit and to bring ideas from concept to reality.

We specialise in

- Product development and design

- Manufacturing operations

- Materials development

- Product use and end of life

We are also part of the Engineering, Materials and Design cluster (EMD Ireland). The cluster is a consortium of seven specialised Enterprise Ireland Technology Gateways operating within the engineering, materials, and design sector.

Describe your role within the Gateway?

Primarily I am accountable for business development, daily operations of the gateway and its strategic growth. All this needs to stay aligned with identified industry need. Within day-to-day operations there is an element of project management, there’s also working closely with my colleagues on their development, a part of the job I enjoy very much.

What is unique about PEM and its presence in North-West region?

PEM is uniquely positioned near the border and can offer not only Enterprise Ireland funding but also InterTrade Ireland, Interreg and Invest NI funding opportunities to start-ups, potential entrepreneurs, SMEs or MNCs. We are in the process of moving to a new premises which will house all our equipment under one roof. There is high demand for precision engineering in the Northwest, we can service those needs.

PEM are at the forefront of precision engineering expertise, and we offer businesses the use of our specialised state-of-the-art equipment and testing facilities for one-off test pieces and for prototyping purposes, but we’re not limited to that, we are always looking for new ways to help businesses.

Can you outline some of the equipment currently available within the gateway?

PEM has in the past two years received significant funding from Enterprise Ireland for:

- 400-600kN range tensile tester

- A material testing suite which includes:

- gas displacement pycnometer

- low force tensile tester (up to 1.2kN)

- micro hardness tester

- universal hardness tester

- A precision engineering suite built around a turning centre and its ancillary equipment

- 5 Axis CNC milling machine – this equipment has just been funded and is still being procured, watch this space!

We also have access to equipment within IT Sligo, we find the best thing is for people to talk to us and we can take it from there.

What are the main benefits for a company collaborating with PEM?

PEM’s research, development & innovation capabilities provide industry with unique support underpinned by the experience and expertise of our PIs. All our PIs have notable research achievements through engagement with industry. Businesses collaborating with PEM benefit from all these achievements and expertise.

PEM can help with your technical, engineering and manufacturing questions and issues. We can help develop projects to answer those questions and solve those issues. For example, we can:

- Develop an initial design concept by taking your idea and bringing it to life using visuals such as CAD models and working drawings, or even a physical 3D print of the product

- Advising and supporting with DFM considerations to help you get to the manufacturing phase of your product development which will save you time and money

- Executing the physical machining or fabrication of your product resulting in either a prototype or the finished article

- Improving or optimising existing products, utilising our onsite testing and simulation capabilities

Crucially we are also here to help navigate the various funding agencies and models that may be available to help fund any work we undertake for businesses.

What is the first step/s a company should consider when considering an R&D project?

Some examples of first steps are:

- Is there a need in the marketplace for your idea, product or process?

- Start to develop a scope for the project, however rough it may be, it helps to focus the mind.

- If you have stakeholders, discuss it with them to get multiple perspectives and flag any early risks

- Give us a call and we can assist with exploring funding opportunities, engineering, design, development, and evaluation

As a new member of the Technology Gateway team what are you most looking forward too?

I am most looking forward to helping businesses solve their issues, become more productive and hopefully see jobs growth – that is a very exciting prospect!

How can a company get in touch with PEM?

Contact Russell Macpherson on:

Email: macpherson.russell@itsligo.ie / pemgateway@itsligo.ie

Website: www.pemcentre.ie/contact-us

Twitter: @PEM_ATUSLIGO

Linkedin: PEM Technology Gateway