Enhancing the performance of a turbine

Precision engineering solutions

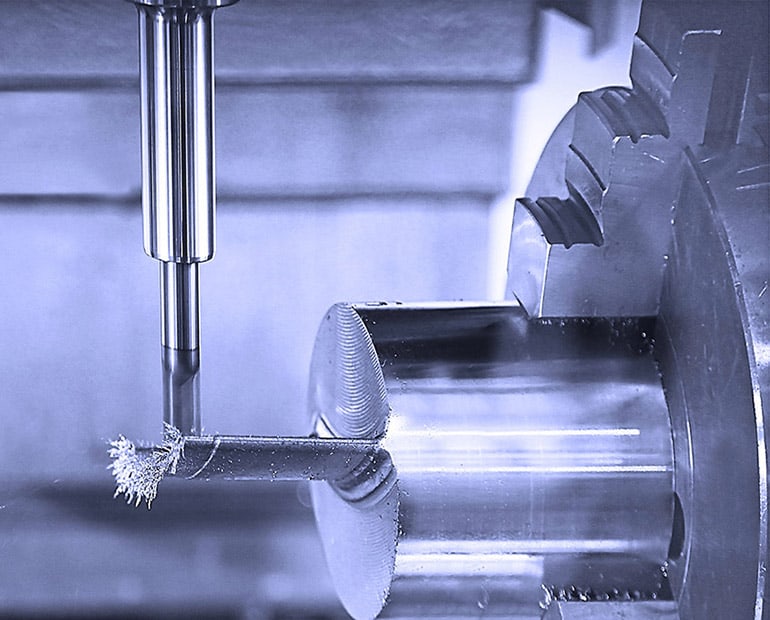

ATA Air Tools (ATA) manufactures and distributes pneumatic air tools to over 50 countries in major industries such as aerospace and automotive. They are the only precision engineering company in the world to provide both tools and consumables for a variety of deburring, material removal and finishing needs – across any material and any application.

Air-driven motor

Pneumatic tools are most commonly powered by compressed air through a vane motor. This type of motor requires lubrication which can be problematic for many applications, in particular in the aerospace sector. ATA has developed an innovative air-driven motor which removes the need for lubricant and also achieves the required torque in a compact design. However, one of ATA’s leading products was performing lower than expected, specifically in relation to the turbine power output and rotational speed.

1,400

distributors

60

countries worldwide

€500,000

project budget

“The work carried out by PEM has proved invaluable in the design of our latest high speed air driven turbine motor. The CFD analysis provided allowed us to experiment with various jet configurations, these were then 3D printed by PEM enabling us to run the necessary power, torque and speed tests. This process allowed us to optimise the motor output while learning a great deal about the flow & expansion of the air through the assembly. I look forward to working with PEM on further design projects in the future.”

Hugh McManus

R&D manager, ATA

The ATA & PEM partnership

The PEM Technology Gateway undertook a design review of the existing product, identifying potential causes for underperformance. Using CAD modelling, Computational Fluid Dynamics (CFD) was used to develop and analyse potential design solutions before rapid prototyping of key components for direct testing.

The change in design improved the motor performance of the product in question, and was subsequently applied across a range of ATA products.