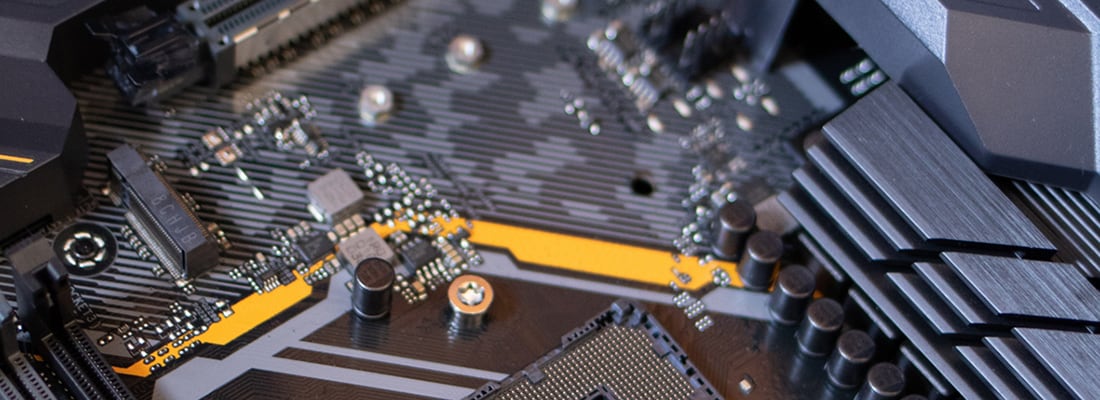

In-situ strain analysis in PCB manufacture

Automotive components and parts supplier

BorgWarner is an automotive components and parts supplier. BorgWarner manufacture powertrain products, manual and automatic transmissions, transmission components, transmission control units, friction materials, turbochargers, engine valve timing system components and drive system components.

Quantify stresses applied on PCBAs

BorgWarner were interested to quantify the stresses applied on PCBAs for an HV Air Heater during an assembly process and whether the stresses applied were within acceptable limits.

IMaR obtained sample printed circuit boards from BorgWarner, sourced suitable uniaxial strain gauges, configured instrumentation and adhered the strain gauges to specified positions on each board. Strain measurements were undertaken in-situ, during the assembly process. IMaR analysed the data and reported the findings, detailing the maximum strain, maximum rate of change of strain and to what extent high strain coincided with high rate of change of strain. IMaR also supplied the raw data to the client.

1

automotive components and parts supplier

1

direct consultancy project

1

project report

“Collaborating with IMaR has been a really instructive experience. They are as flexible as reliable, adapting always to the circumstances and supplying a high-quality service.“

Julio Carrera

Advanced Senior Product Engineer, BorgWarner Limited

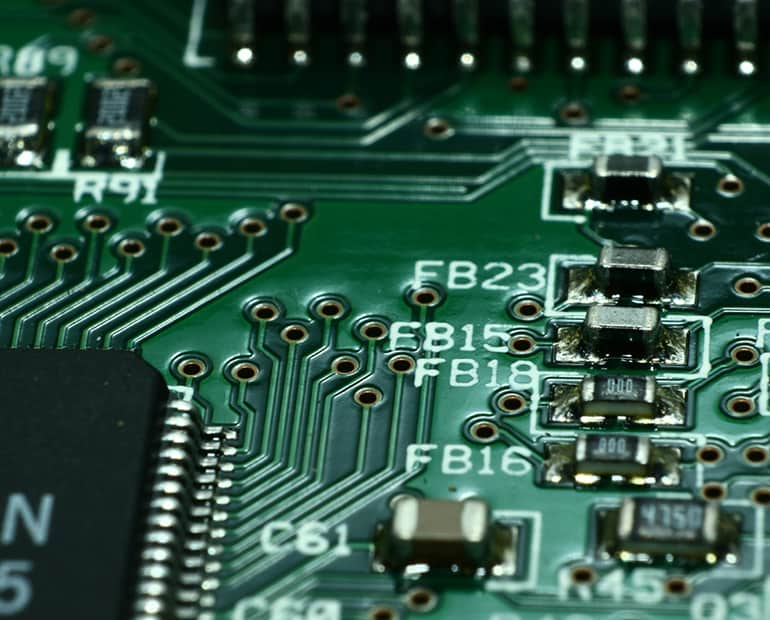

The BorgWarner & IMaR Technology Gateway partnership

The client obtained a profile of the stresses applied during the assembly process on the PCBA boards, and could be confident, based on the results of the tests and with reference to industrial standards, that the process did not overstress the product.